Rivets

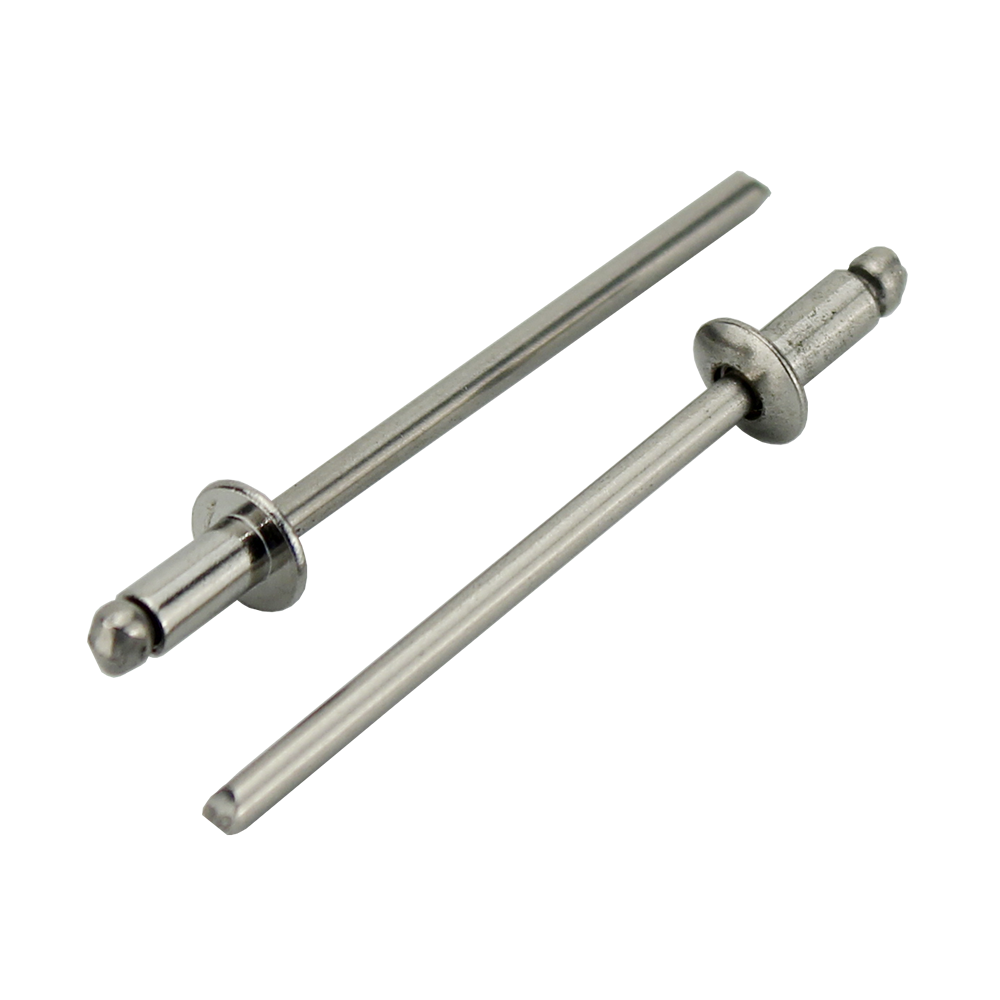

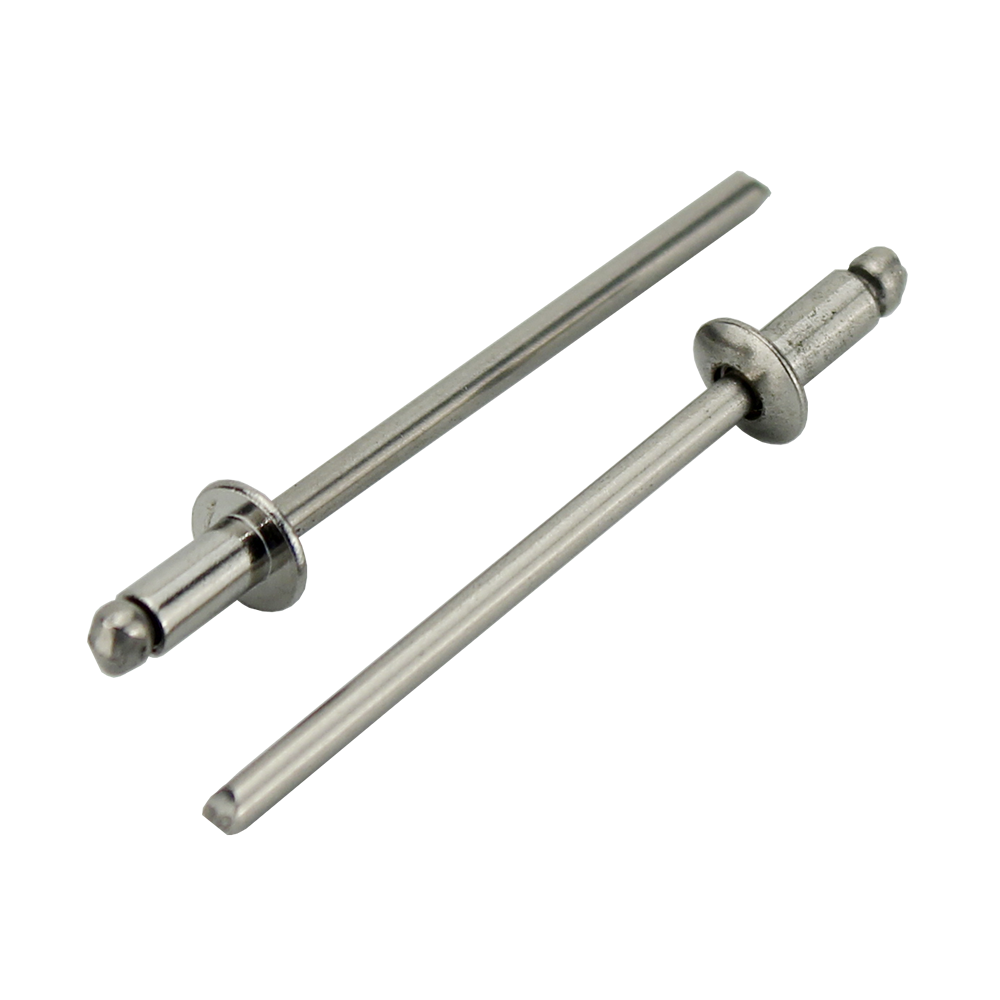

Rivets are fastening elements that only need to be applied once. When opening the connection, the rivet must be irrevocably destroyed. Rivets are therefore one-time elements and are manufactured in stainless steel and steel.

1. Rivets

2. The solid rivet to knock in

3. The blind rivet as modern rivet joint

4. Our delivery program of rivets - simply buy online in our Online Shop

5. Which types of rivets are still in use today?

6. The rivet form A corrugated

7. The rivet form A - ungrooved

8. The assembly of rivets with pin made of steel or stainless steel with a riveting pliers

9. Further links on the subject of rivets

The solid rivet to knock in

The solid rivets, or simply called steel rivets or stainless steel rivets, are actually only used in the older and earlier years on heavy steel constructions, when welding had not yet been invented and/or was not yet so far advanced. Riveting was then the only possibility to permanently and inseparably join two separate steel or sheet metal construction parts. Inseparable in this case means that it is not possible to loosen the rivets in order to separate the components again. In order to enable the components to be separated, the rivet connection must always be destroyed. A solid rivet is always cut off at the head and the upset pin, which is usually firmly seated in the hole, must then be drilled out. This is the only way to enable the non-destructive dismantling of two components connected with solid rivets.

The solid rivets, or simply called steel rivets or stainless steel rivets, are actually only used in the older and earlier years on heavy steel constructions, when welding had not yet been invented and/or was not yet so far advanced. Riveting was then the only possibility to permanently and inseparably join two separate steel or sheet metal construction parts. Inseparable in this case means that it is not possible to loosen the rivets in order to separate the components again. In order to enable the components to be separated, the rivet connection must always be destroyed. A solid rivet is always cut off at the head and the upset pin, which is usually firmly seated in the hole, must then be drilled out. This is the only way to enable the non-destructive dismantling of two components connected with solid rivets.The blind rivet as modern rivet joint

Our delivery program of rivets - simply buy online in our Online Shop

Our range of rivets, also known as hollow rivets, has become more and more complete in recent years, so that today we can supply industry and private users quickly with the right blind rivets throughout Europe. In our online shop you have the possibility to choose your suitable blind rivets with the desired suitable small quantity and so you can easily arrange different sizes and quantities. Then add your articles to the shopping cart and you can now pay comfortably with the desired payment method. After we have received your order and your online purchase, we will assemble your goods in our warehouse and the order will leave our company to travel to you. After a few days you will receive your order with the desired blind rivets by the transport company.

Our range of rivets, also known as hollow rivets, has become more and more complete in recent years, so that today we can supply industry and private users quickly with the right blind rivets throughout Europe. In our online shop you have the possibility to choose your suitable blind rivets with the desired suitable small quantity and so you can easily arrange different sizes and quantities. Then add your articles to the shopping cart and you can now pay comfortably with the desired payment method. After we have received your order and your online purchase, we will assemble your goods in our warehouse and the order will leave our company to travel to you. After a few days you will receive your order with the desired blind rivets by the transport company.Which types of rivets are still in use today?

The rivet form A corrugated

The rivet form A - ungrooved

The assembly of rivets with pin made of steel or stainless steel with a riveting pliers

Further links on the subject of rivets

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , no shipping costs (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , no shipping costs (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , no shipping costs (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

including 19% VAT. , plus shipping (Standard)

German

German