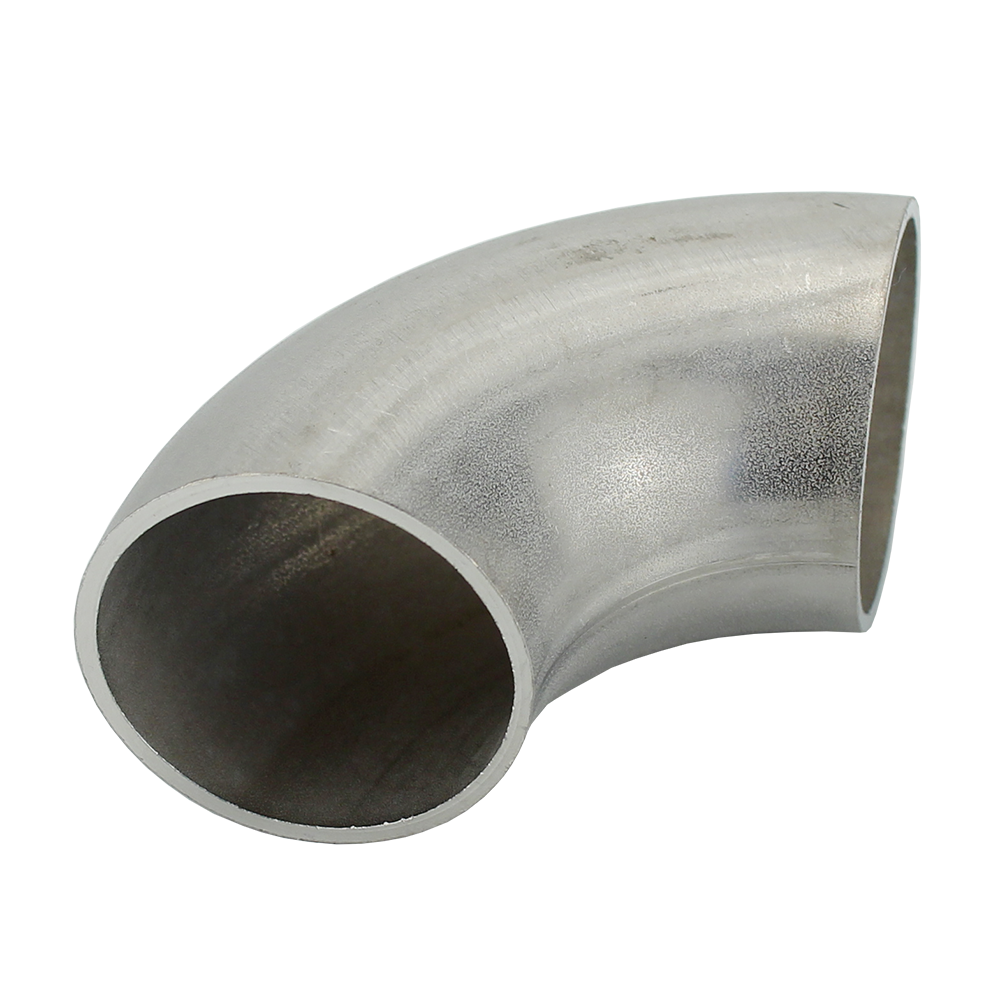

Weld-In Elbows

Weld-in elbows and pipe bends are perfect elements which are mainly used in railing construction. But such pipe bends are also indispensable in pipeline construction.

1. Weld-in elbows and pipe bends

2. Our delivery program of welding elbows / welding elbows or pipe bends - Buy online in our online shop

3. The installation of pipe bends or weld-in elbows

4. Similar websites around the topic welding elbow - pipe elbow

Welding elbows or pipe bends made of V2A stainless steel are a small helper that can quickly and cost-effectively initiate changes in the direction of stainless steel pipes. The pipe to be bent does not have to be diverted by a pipe bender. Because the problem is then often that the bends do not happen exactly where they would be desired. After such a bend of a string pipe a change would no longer be possible, because the piece would then have to be cut out. For exactly these reasons and the time span, the use of welding elbows or pipe bends made of stainless steel is used without exception. These pipe bends or weld-in bends are inexpensive to have and prefabricated in such a way that they can be simply attached to the respective pipes without reworking and quickly welded all around. Then the weld seam only has to be sanded, whereby the pipe bend is of course partially or completely sanded. For this reason, pipe bends or weld-in bends that are not ground are usually used on railings or piping systems. Of course, there are also ground versions of welding elbows / welding elbows or pipe elbows made of stainless steel, but this usually makes no sense to use them, because they anyway have to be ground and sanded with the weld seam to create a complete adapted sanding pattern. For more information on the topic: Welding elbows or pipe bends, please visit our blog. Mainly these bent pipe pieces find their application areas in metal processing companies and locksmith's shops, which are active in railing construction in order to produce modern stainless steel railings for their customers. However, this is only one of the many other areas of application for tube bends made of V2A or V4A. In particular, but also in pipeline construction in the chemical industry, thousands of metres of pipe bends or weld-on bends are welded and processed every day. Afterwards the most different liquids flow through these piping systems in order to connect plants and containers with pump systems and gate valves.

Welding elbows or pipe bends made of V2A stainless steel are a small helper that can quickly and cost-effectively initiate changes in the direction of stainless steel pipes. The pipe to be bent does not have to be diverted by a pipe bender. Because the problem is then often that the bends do not happen exactly where they would be desired. After such a bend of a string pipe a change would no longer be possible, because the piece would then have to be cut out. For exactly these reasons and the time span, the use of welding elbows or pipe bends made of stainless steel is used without exception. These pipe bends or weld-in bends are inexpensive to have and prefabricated in such a way that they can be simply attached to the respective pipes without reworking and quickly welded all around. Then the weld seam only has to be sanded, whereby the pipe bend is of course partially or completely sanded. For this reason, pipe bends or weld-in bends that are not ground are usually used on railings or piping systems. Of course, there are also ground versions of welding elbows / welding elbows or pipe elbows made of stainless steel, but this usually makes no sense to use them, because they anyway have to be ground and sanded with the weld seam to create a complete adapted sanding pattern. For more information on the topic: Welding elbows or pipe bends, please visit our blog. Mainly these bent pipe pieces find their application areas in metal processing companies and locksmith's shops, which are active in railing construction in order to produce modern stainless steel railings for their customers. However, this is only one of the many other areas of application for tube bends made of V2A or V4A. In particular, but also in pipeline construction in the chemical industry, thousands of metres of pipe bends or weld-on bends are welded and processed every day. Afterwards the most different liquids flow through these piping systems in order to connect plants and containers with pump systems and gate valves.Our delivery program of welding elbows / welding elbows or pipe bends - Buy online in our online shop

Today, pipe bends are indispensable in the processing industry. Today, these are welded and installed every day in all possible areas in order to complete systems and hand them over to customers. At the beginning of our company we had not really thought of this area as a priority in order to offer pipe bends of all kinds in our online shop for our customers. After some requests of our long-time customers, which we supply with many other products, we have also started to search for a supplier who can supply us with pipe bends made of V2A or V4A in unpolished form and also in polished form. This search was not easy, but after a long time we finally found what we were looking for and since then we have been able to offer our customers all over Europe welded elbows in many shapes and supply them quickly. With our online shop, we offer our customers the opportunity to order their products at low prices around the clock and have them delivered to their homes conveniently. So we have decided to make the online shop even more secure and to convert the entire website to an encrypted version of the SSL certificate. This is now already completed and the entire website has been running serh long over this certificate. This only has advantages for you as a customer if you order your welding sheets in our online shop and your data is very secure and cannot be tapped by third parties when exporting to our connected systems. At the same time, we would also like to explain to you how a purchase in our online shop should proceed exactly, so that you can buy your pipe bends uncomplicatedly and quickly from us cheaply. First of all, put all the products you want to buy into the shopping cart. Once you have collected all the products and placed them in the basket, you will be asked to create a customer or guest account so that you can store all your relevant delivery data. These are also used to create invoices in our system. If you would now like to complete your purchase, press the "Checkout" button and many different payment options will be suggested to you. Now you can select the best payment option for you and confirm it by your payment and complete the purchase of your welding sheets. If the payment was successful, you will automatically receive an email with the order confirmation from our system. At the same time your goods will be registered by our system and forwarded to our warehouse. Here your weld-on elbows or weld-in elbows are put together and handed over to the responsible transport company. Now your goods should arrive after a few days with you or your company.

Today, pipe bends are indispensable in the processing industry. Today, these are welded and installed every day in all possible areas in order to complete systems and hand them over to customers. At the beginning of our company we had not really thought of this area as a priority in order to offer pipe bends of all kinds in our online shop for our customers. After some requests of our long-time customers, which we supply with many other products, we have also started to search for a supplier who can supply us with pipe bends made of V2A or V4A in unpolished form and also in polished form. This search was not easy, but after a long time we finally found what we were looking for and since then we have been able to offer our customers all over Europe welded elbows in many shapes and supply them quickly. With our online shop, we offer our customers the opportunity to order their products at low prices around the clock and have them delivered to their homes conveniently. So we have decided to make the online shop even more secure and to convert the entire website to an encrypted version of the SSL certificate. This is now already completed and the entire website has been running serh long over this certificate. This only has advantages for you as a customer if you order your welding sheets in our online shop and your data is very secure and cannot be tapped by third parties when exporting to our connected systems. At the same time, we would also like to explain to you how a purchase in our online shop should proceed exactly, so that you can buy your pipe bends uncomplicatedly and quickly from us cheaply. First of all, put all the products you want to buy into the shopping cart. Once you have collected all the products and placed them in the basket, you will be asked to create a customer or guest account so that you can store all your relevant delivery data. These are also used to create invoices in our system. If you would now like to complete your purchase, press the "Checkout" button and many different payment options will be suggested to you. Now you can select the best payment option for you and confirm it by your payment and complete the purchase of your welding sheets. If the payment was successful, you will automatically receive an email with the order confirmation from our system. At the same time your goods will be registered by our system and forwarded to our warehouse. Here your weld-on elbows or weld-in elbows are put together and handed over to the responsible transport company. Now your goods should arrive after a few days with you or your company.The installation of pipe bends or weld-in elbows

When installing a pipe elbow or welding elbow, it is important that the surfaces of the pipes are cut flat ond without degrees on the outside. Then the pipe elbow or the welding elbow can be attached to the pipe using two clamping tongs. Align the pipe pairs with each other in such a way that they do not protrude beyond the adjacent pipe. Now the pipe bend is "tacked" to the pipe. Once this has been done, the pliers can be removed again. Now the tongs will be attached to the second side of the elbow or the welding elbow and connected to the steel pipe. Also here again the "tacking" of the parts takes place so that the correct seat can be checked again and could be corrected if necessary again fast. If now the alignment of the welding bend or the pipe bend is okay, then the seams can be pulled around the entire pipe. This is done again on both sides of the pipe bend. Once this section has been completed, the welding seams can be neatly sanded with a belt sanding machine. If no more unevenness of the pipe bends and the straight pipes can be seen, the next step can be initiated. Now the fine grinding takes place with 240 grains of the entire pipe bend and the steel pipes to achieve a clean fine contour and haptic. This step is always performed by a belt grinder. When fine grinding or finishing, guide the belt grinder to the pair of tubes and apply pressure only completely to achieve an even grinding pattern over all parts. It is important that the sanding belt is never guided selectively, but always rotates over the pipe surfaces, so that no deeper contours can develop and a perfect sanding pattern marks the end of this work as the end.

When installing a pipe elbow or welding elbow, it is important that the surfaces of the pipes are cut flat ond without degrees on the outside. Then the pipe elbow or the welding elbow can be attached to the pipe using two clamping tongs. Align the pipe pairs with each other in such a way that they do not protrude beyond the adjacent pipe. Now the pipe bend is "tacked" to the pipe. Once this has been done, the pliers can be removed again. Now the tongs will be attached to the second side of the elbow or the welding elbow and connected to the steel pipe. Also here again the "tacking" of the parts takes place so that the correct seat can be checked again and could be corrected if necessary again fast. If now the alignment of the welding bend or the pipe bend is okay, then the seams can be pulled around the entire pipe. This is done again on both sides of the pipe bend. Once this section has been completed, the welding seams can be neatly sanded with a belt sanding machine. If no more unevenness of the pipe bends and the straight pipes can be seen, the next step can be initiated. Now the fine grinding takes place with 240 grains of the entire pipe bend and the steel pipes to achieve a clean fine contour and haptic. This step is always performed by a belt grinder. When fine grinding or finishing, guide the belt grinder to the pair of tubes and apply pressure only completely to achieve an even grinding pattern over all parts. It is important that the sanding belt is never guided selectively, but always rotates over the pipe surfaces, so that no deeper contours can develop and a perfect sanding pattern marks the end of this work as the end.Similar websites around the topic welding elbow - pipe elbow

- https://de.wikipedia.org/wiki/Rohr_(Technik)

- https://de.wiktionary.org/wiki/Rohrbogen

- https://www.wortbedeutung.info/Rohrbogen/

including 19% VAT. , plus shipping (Standard)

| From | Price per unit |

|---|---|

| 10 | 3,65 € |

| 50 | 3,49 € |

| 100 | 3,28 € |

| 500 | 3,21 € |

including 19% VAT. , plus shipping (Standard)

| From | Price per unit |

|---|---|

| 10 | 4,02 € |

| 50 | 3,83 € |

| 100 | 3,59 € |

| 500 | 3,51 € |

including 19% VAT. , plus shipping (Standard)

| From | Price per unit |

|---|---|

| 10 | 4,75 € |

| 50 | 4,51 € |

| 100 | 4,21 € |

| 500 | 4,12 € |

German

German